Printing

1. Use our print lists

Use our print lists to find out specifics and advices how to print every part of the craft. You find them on the right side of pages of each section.

2. Print sections in this suggested order

1 - PROPELLER : 3x, PROP HOLDER : 3x, RUDDER ADAPTER : 3x

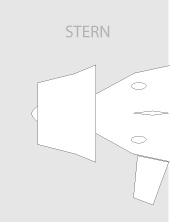

2 - STERN SECTION

2 - V-THRUSTER SECTION : 2x

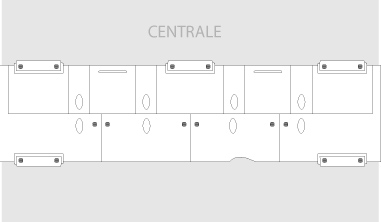

3 - CENTRALE SECTION

4 - BOW SECTION

5 - DRY COMPARTMENT

6 - BATTERY PACK 2X

Print settings

Unfortunetly we can´t provide exact print settings. All depends on material you print from, quality and amount of filament you can affort and time you willing to invest in comlete build. In general and as usuall better quality is better and in our cause, due to specials as buoyancy, harsh enviroment printed parts will be placed, higher infill density is definetly better as well. So calculate the ratio for yourself before starting to print. If you plan to use craft for serious missions in salt water with long term of operations, consider set the material, quality and infill as high as you can. If you plan just create craft for some fun, you can set it all bit lower.

Please check our article about printing of waterproof objects for underwater applications to find more specific solutions

Small recapitulation of obvious for decide making

1. Greater printing layer setings (lower quality of print) is more risky that part will be non water tight.

2. Lower infill (bigger spaces of air between bulkheads inside printed part) means more buoyant part will be and depth in which the part can be use will be reduced as well.

3. Higher quality of print and higher density of infill means long times of printing. In some causes as much as 14 hours and more for one part (Depends on type of printer and printing settings).

4. Higher quality of print and higher density of infill means more fillament you need.

5. PETG filament is more durable, but more expensive than PLA.

6. PLA filament is way more eco / ocean friendly but has worse characteristics for use in water.

Coating of printed parts

Not all filaments for 3D printing are properly water tight. While PET family filaments are belived are water tight (when printed wiht greater density and infill), PLA filament is believed that is not (at least for longer times of exposition in the water). Even if you print with great infill, water could soon slowly soak in to your parts, change boyancy, damage your electronic inside dry section of AUV, wich will end in waste of everything you done on your project. Thus all parts, specialy sealing caps could be coated with watertight medium.

If you want to apply some coating, chose medium which is water resistant and best of all salt water resistant. You could find some brands in marine stores.

NEVER use coaters which are toxic to marine life for obvious reasons! Check our EcoGuide for more.

This documentation book is released under the CC-NC-SA 4.0 License.